Environment Standards / Guideline

| Environmental management system | ISO 14001:2015 |

| Energy management system | ISO 50001:2018 / Solomon Energy Intensity Index |

| Water management | Water Stress Index (WSI) / ISO14046 Water Footprint |

| Waste management | Reduce, Reuse & Recycle (3Rs) |

Environmental Dimension Targets

Environmental Management Program

Operational Eco-Efficiency

Bangchak determined to emphasize the efficient use of natural resources in its production process, the highest production capacity but the least waste and pollutions. The company has also adopted the environmental management system into use. The system is in accordance with ISO 14001: 2015 regarding the use of natural resources and pollution control to drive for continuous development under proactive policies in compliance with the Green Industry Level 5: Green Network, and promoted environmental management practices to all stakeholders throughout the supply chain, communities and consumers in order to become a green network. This too, demonstrated the company’s commitment to environmental development which is becoming the corporate culture in doing business with social responsibility today.

Eco-Efficiency

Bangchak realizes the importance of balancing economic growth and environmental impact in pursuing for sustainable development and determined to uses eco-efficiency as an indicator. By which, the company uses earnings before interest, tax, depreciation and amortization (EBITDA) to reflect economic growth and uses the amount of GHG emission which is an important environmental aspect of the petroleum industry to reflect the environmental impacts. A high ecoefficiency value indicates high efficiency production and low environmental impacts.

Note: EBITDA and carbon dioxide equivalent (scope 1 and 2) of the refinery and market businesses.

Energy Consumption

Energy is an essential input driving businesses and the production process of various industries. However, energy consumption contributes to climate change impacts from greenhouse gas (GHG) emissions. Global businesses are aware of this fact and determined to set up their target for sustainable development in alignment with SDG 7 & SDG 13 to help reduce the adverse impacts of energy consumption and GHG emissions.

Bangchak has recognized the importance and impacts of energy consumption in business operations and taken into consideration the establishment of energy management system in accordance with ISO 50001 for the refinery business and oil distribution terminal since 2014. In 2019, the company was the first company in Thailand certified by ISO 50001: 2018. This proves the true commitment of the company and its capability in energy management in line with international standards and to be the foundation for sustainable growth in the future.

Bangchak Group is ready to drive the development of the Low-Carbon Society with the BCP NET Plan comprising

4 Dimensions

in order to achieve organizational

Carbon Neutrality by 2030 and Net Zero by 2050

emphasizing tangible processes and long-term results.

Read MoreLow-Carbon Product

The company has continuously developed eco-friendly petroleum products with a mixture of ethanol and biodiesel which are good for the engine. These products are environmental friendly since they alleviate PM2.5 dust pollution. They also increase farmers’ income.

Eco-Friendly Transportation

Project to Increase Proportion of Oil Transportation by Semi-Trailer

The company manages transportation vehicles by changing from 2 single trucks to a semi-trailer (40,000 liters load). This change helps reduce not only the cost of transportation but also the GHG emissions per unit of oil.

The proportion of products transportation by trucks decrease the GHG emissions

Water Consumption

Bangchak, as one in the energy industry consuming high quantity of water, recognizes the importance of water management as well as the increase in efficiency improvement of water consumption. Therefore, the company set targets for the reduction and control of new water withdrawal, including water management through the use of innovative tools and technology.In addition, the company uses Water Stress Index (WSI) of 25 Watersheds level in Thailand and the world class WSI(1) to assess the water scarcity footprint of the company’s products in accordance with ISO14046 guidelines.

Percentage of new water usage reduction compared to water demand in that year (Percentage and amount of water that can be reduced)

*Compared to baseline year 2015 from reusing condensate water in boilers and the 4 refinery unit plus treated water from oil treatment unit using RO, and include treated water from wastewater treatment units using RO for cooling towers

Number of significant oil and chemical spills (more than 100 Barrels / incident)

Oil and Chemical Spill Management

Bangchak is aware of the risks and adverse impacts of oil and chemical spills from the business operations which were our materiality topics. Therefore, Bangchak prioritizes safety in every business operation and environment protection in every business activity to prevent oil and chemical spills affecting society and environment throughout the value chain: from crude oil transportation to our refinery, from oil product transportation to our oil depot and terminals, and from service stations to our customers.

Air Emissions Management

Air pollution is an important environmental issue for the energy industry since it is harmful to human health and affect quality of life of people in the society. This is especially relevant nowadays on the issue of particulate matter with 2.5 micron in size (PM 2.5) which has become a serious environmental issue in Thailand. Therefore, Bangchak takes careful steps to monitor and control the quality of air emissions emitted to the environment in order to prevent and mitigate impacts on employees, contractors working at Bangchak refinery, communities and environment around the Bangchak refinery and other operating sits of the company.

Control the release of air pollution to not exceed 80% of control limit

Waste and Unused Materials Management

Bangchak places strong emphasis on maximizing resource efficiency by applying the 3R principles—Reduce, Reuse, and Recycle—to optimize waste utilization across both office areas and refinery operations. These efforts have been continuously developed and expanded into the 5R and 7R concepts, which include:

- Reject: Avoiding the use of environmentally unfriendly materials or chemicals.

- Recovery: Utilizing waste materials.

- Rethink: Rethinking comprehensive utilization before disposal.

- Repurpose: Repurposing used materials by finding alternative uses.

As part of its commitment to continuous improvement, Bangchak has adopted and been certified under the ISO 14001 Environmental Management System. This internationally recognized framework supports the implementation of systematic waste audits, helping the company identify opportunities to improve waste management performance across all operations.

Bangchak is firmly committed to achieving its Zero Waste to Landfill target, as well as eliminating waste incineration without energy recovery. In addition, the company aims to reduce waste generation intensity by 3% by 2025.

2024 Performance

The Refinery and Trading Business Group (RFBG) has implemented a Zero Waste to Landfill policy and has successfully achieved this target since 2015. To support this policy, the SHEE Promotion team has actively worked to raise employee awareness on waste reduction and the importance of zero waste to landfill. Each year, RFBG summarizes its performance data related to Zero Waste to Landfill for inclusion in the Sustainability Report, certified by a third party. In 2021, RFBG was awarded the Zero Waste to Landfill Certificate by the Department of Industrial Works.

Waste management aligned with 3Rs (%)

Biodiversity

Biodiversity and Forest Management

Rapid economic growth in recent years has led to the use of natural resources and disturbance in natural ecosystems. It can result in biodiversity losses and habitat destruction for living organisms and ecosystems, which can have negative consequences on human quality of life, such as a decrease in food sources, and impacts on economic activity, such as decreased productivity. Bangchak Company is aware of both positive and negative effects on biodiversity from its business operations by making biodiversity an essential issue in the Sustainable Policy.

Disclosure of EIAs / SIAs

Environmental Violations

| Environmental Violations | 2021 | 2022 | 2023 | 2024 |

|---|---|---|---|---|

| Number of violations of legal obligations / regulations | 0 | 0 | 0 | 0 |

| Amount of fines penalties related to the above: THB | 0 | 0 | 0 | 0 |

| Environmental liability accured at year end: THB | 0 | 0 | 0 | 0 |

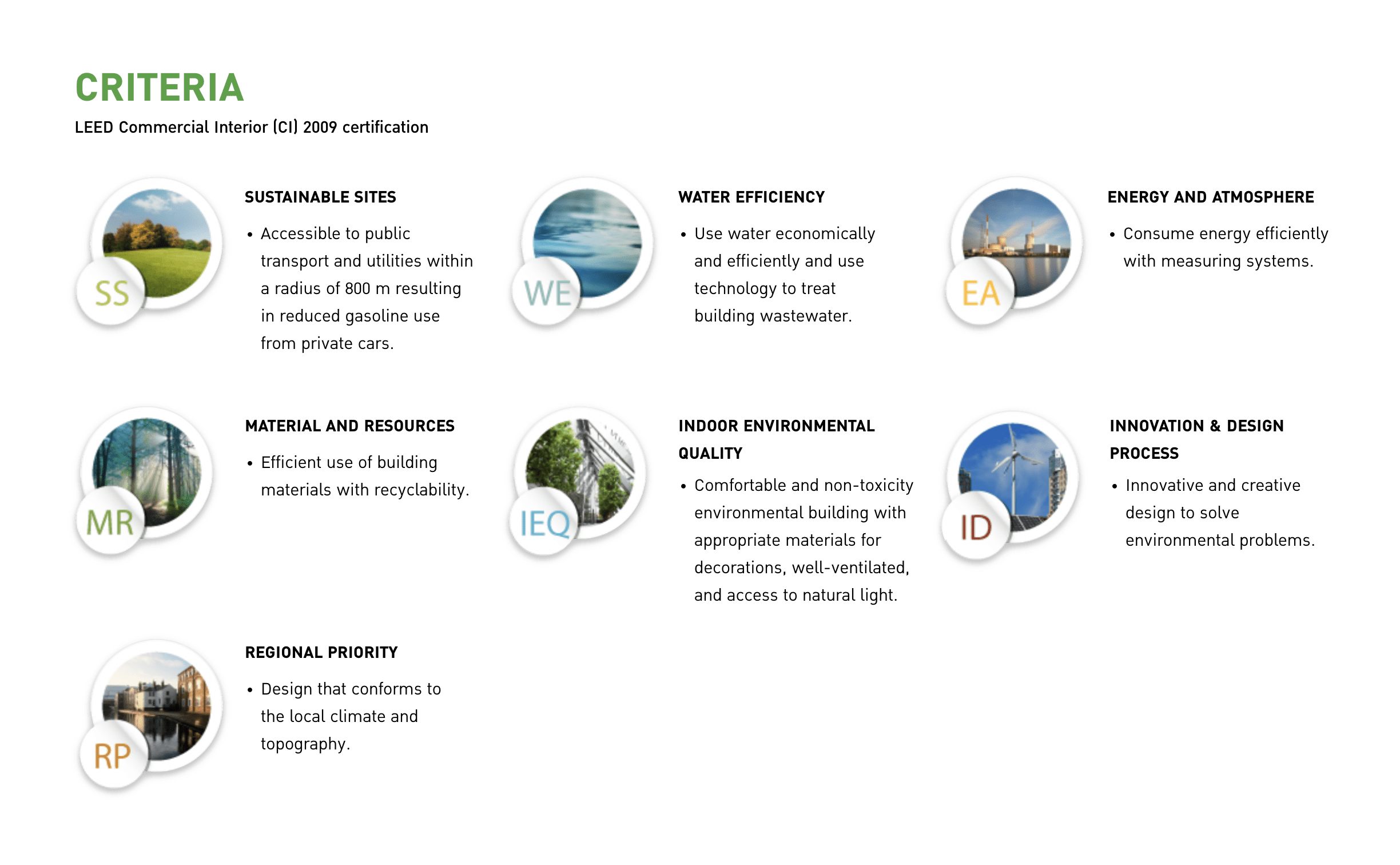

Green Building

Leadership in Energy and Environmental Design : LEED Leadership in Energy and Environmental Design (LEED) is a green building standard that addresses energy use, environmental issues, and occupant quality of life. The U.S. Green Building Council (USGBC) created it to evaluate the performance of buildings in building design, construction, and use.

Bangchak's head office building has been certified with LEED Platinum, ranked No. 1 in Thailand in the LEED for Commercial Interior (LEED CI) category in Thailand's largest area. The office building is decorated in an environmental-friendly architectural design and constructed by considering saving energy and water, air quality control, reducing carbon dioxide emissions, and efficient use of resources. With this concept, this building can improve the quality of residential lives, building users, and the environment inside the building.

Environmental Activities

กลุ่มบางจากฯ กับเส้นทาง Blue Carbon ในทะเลตะวันออก

ลดขยะต้นทางกับบางจากฯ

กิจกรรม Road Show และ Workshop คัดแยกขยะ

โครงการคัดแยกขยะเพื่อรีไซเคิล

โครงการพอ พัก ผัก อาคาร M-Tower

บางจากฯ ร่วมภาคีเครือข่าย จัดงานวันหิ่งห้อยโลก คุ้งบางกะเจ้า ประจำปี 2567 ส่งเสริมความหลากหลายทางชีวภาพ สนับสนุนเศรษฐกิจท้องถิ่น สร้างรายได้การท่องเที่ยวเชิงอนุรักษ์

Financial Times ประกาศให้บางจากฯ เป็นองค์กรชั้นนำด้านสภาพภูมิอากาศ ในภูมิภาคเอเชียแปซิฟิก (Asia-Pacific Climate Leaders 2024) บริษัทไทยรายแรกและหนึ่งเดียวในอุตสาหกรรมพลังงานและสาธารณูปโภค